Interlab supplies an extensive range of Borosil Glassware, view our range here and read on for more information.

Autoclaving BOROSIL Glassware

Borosil recommends the following safety practices when autoclaving laboratory glassware:

· Never autoclave items containing corrosives (e.g. acids, bases, phenol), solvents or volatiles (e.g. ethanol, methanol, chloroform) or radioactive materials.

· Place individual glassware vessels within a heat resistant plastic or metal tray on a shelf or rack. Never place them directly on the Autoclave base or floor. Always maintain space between glass vessels to give them room to expand while heating, and to prevent them from hitting other vessels when entering or leaving the Autoclave.

· To prevent bottles from getting shattered during pressurisation, the caps of the vessels with liquids must be loosened completely before loading.

· Always use the slow exhaust or liquid cool cycle when autoclaving liquids, to prevent the liquid from boiling over, causing loss of the contents.

· Never autoclave a sealed vessel containing liquids as this may result in an explosion of the super-heated liquid and steam during the cycle, or when the vessel is opened.

· Wear heat-resistant gloves when opening the Autoclave door after a cycle. When removing items from an Autoclave, wear at least a rubber apron, rubber sleeve protectors and heat-resistant gloves should be worn.

· Do not tighten caps on the vessels immediately after autoclaving as the cap or the vessel may get shattered due to the vacuum resulting from the cooling of the steam in the vessel. This is particularly important for larger vessels. Caps with liners may have their liner sucked into the vessel if the cap on the vessel opening is not loose enough.

· Do not put hot glassware, especially large bottles, from an Autoclave (or any other heat source) on to a cold bench top. The stress that is induced will often cause the base of the vessel to crack or fall off, releasing its hot contents.

Cleaning :

Cleaning of new glassware:

· New glassware is slightly alkaline in reaction. New glassware should be soaked for about 2 to 3 hours in acidic water ( 1 % solution of hydrochloric acid or nitric acid ). Rinse with water and then soak the empty glassware in a basin / tub containing Suitable cleaning agent / solution for 20 to 30 minutes. Follow the procedure of cleaning as given below.

Cleaning of regular glassware:

· Remove the content and markings of glassware before washing.

· Glassware should be brought to ambient temperature before subjecting them for cleaning, Rinse with water and then soak the empty glassware in a basin / tub containing Suitable cleaning agent or any suitable detergent solution.

· Do not use brushes with metallic bristles vigorously as it may form scratches on the surface.

· After applying cleaning agents thoroughly rinse glassware with tap water.

· Finally rinse the glassware with purified water.

· Dry glassware in a drying oven at 0 temperature at 60 C and store in a designated place.

· Strong alkali should not be used for cleaning of glassware. Also use of Chromic acid, sulphuric acid mixture is not recommended because of hazardous and toxic nature of the material.

· Place Pipettes with their tips down, in a cylinder or tall jar of water, immediately after use. Do not drop them into the jar as this may break or chip the tips and render the Pipettes useless for taking accurate measurements.

· A pad of cotton or glass wool at the base of the jar will help to prevent breaking of the tips.

· Ensure that the water level is high enough to immerse the greater portion of all or each of the Pipettes. Then drain the Pipettes and transfer them into a cylinder or jar containing any Suitable cleaning agent or any suitable detergent solution

· Drain the pipette and run tap water over and through them until all contents are removed.

· Soak the Pipettes in purified water for at least one hour.

· Remove them and dry the external surface with a cloth, shake out the water and dry in an oven.

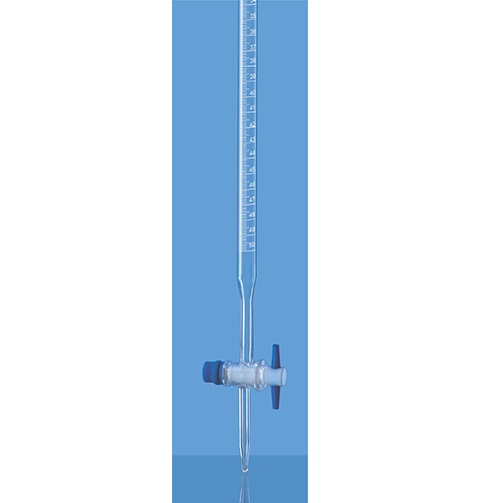

· Remove stopcock key and wash the burette with Suitable cleaning agent or any other suitable detergent solution

· Rinse with tap water until all the dirt is removed. Then rinse with purified water.

· Wash the stopcock key separately.

· Before the stopcock key is replaced in the burette, lubricate the joint with a small amount of lubricant. Remember that burette stopcock keys are not interchangeable.

· Always cover tip of burettes with butter paper or aluminium foil, when not in use.

Culture Tubes:

· Culture tubes which have been used previously must be sterilized before cleaning.

· The best general method for sterilising culture tubes is by autoclaving for 30 minutes at 0 121 C (15 lb pressure).

· Media which solidify on cooling should be poured out while the tubes are hot.

· After the tubes are emptied, brush with Suitable cleaning agent.

· Rinse thoroughly with tap water, rinse with purified water, shake out the water and dry in oven.

· Serological Tubes should be chemically clean but don’t need to be sterile.

· It is imperative when washing serological glassware that all acid, alkali and detergent be completely removed. Both acid and alkali in small amounts destroy complement and in larger amounts produce hemolysis.

· Detergents interfere with serologic reactions.

Technical Information

The products represent optimum mechanical, thermal and chemical behaviour. This glass is used in laboratories as well as for industrial applications, where thermal shock resistance, mechanical resistance as well as unusual chemical resistance are required. Borosil glass is a low alkali borosilicate Type 3.3 glass.

Thermal Properties

· Borosil glass has a low co-efficient of thermal expansion. Consequently, the thermal stresses under a given temperature gradient are also low. The glass can withstand higher temperature gradients and also sudden temperature changes / thermal shocks.

· Minute scratching of the glass surface can, however, reduce its thermal resistance. ‘Strain Point’ should be regarded as the maximum safe operating temperature for Borosil glassware.

· When heated above 500°C, the glass may acquire permanent stresses on cooling.

· All Borosil laboratory ware is annealed in a modern Lehr, under strictly controlled conditions to ensure minimal residual stresses in the products. The typical thermal properties of Borosil glassware are mentioned below :

Coefficient of Linear Expansion 32.5×102cm / cm / °C

Strain Point 515°C

Annealing Point 565°C

Softening Point 820°C

Specific Heat 0.2

Thermal Conductifity (Cal / cm3 / °C / sec) 0.0027

Chemical Data

· BOROSIL 3.3 Glass is highly resistant to water, neutral and acid solutions, concentrated acids and acid mixtures, and to chorine, bromine, iodine and organic substances. The chemical resistance of this glass is superior to that of most metals and other materials, even when exposed to long processing periods and temperatures above 100 ºC.

Safe Use of Glassware

Borosil laboratory apparatus is designed to perform efficiently and last long, provided it is used with proper care.

· View HERE on extending the maximum life and performance on Borosil Glassware

· All laboratory glassware will withstand to thermal shock of 120 °C

Mixing and Stirring

· Always use a teflon sleeve or a similar device on stirring rods, to prevent scratching of the inside of the vessel.

· Never mix sulphuric acid and water inside a glass measuring cylinder. The heat caused by the reaction can break the base of the cylinder.

Vacuum and Pressure

· Never use glassware beyond the recommended safe limit.

· Always use a safety screen when working with glassware subjected to pressure or vacuum.

· Never subject glassware to sudden pressure changes

Joining and Separating Glass Apparatus

· When storing glass stopcocks and joints, insert a thin strip of paper between the joint surfaces to prevent them from sticking.

· Glass stopcocks on Burettes and Separating Funnels require frequent lubrication to prevent them from sticking.

· When using lubricants, it is advisable to apply a light coat of grease all around the upper part of the joint. Use only a small amount, and avoid greasing the part of the joint that comes in contact with the inside of the apparatus.

Personal Safety

· Use tongs or asbestos gloves to remove any glassware from heat.

· Protective gloves, safety shoes, aprons and goggles should be worn to safeguard against chemical accidents, spilling or splattering.

Information supplied courtesy of borosil.com More detailed and technical information on the care of glassware can be found here and here

If you have any questions, about Extending the life of glassware, get in touch with Interlab today! Email us at sales@interlab.co.nz or just give us a FREE call on 0508 331 331