When it comes to selecting a lab balance, precision, accuracy, and suitability for your specific applications are crucial factors to consider. Whether you’re working in a research laboratory, quality control environment, or any other setting that requires accurate measurements, choosing the right balance is essential. To help you make an informed decision, here are some key points to consider:

1. Balance Mechanism:

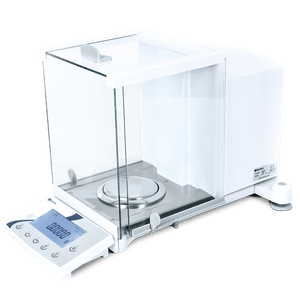

- Electromagnetic Compensation Block: This mechanism relies on the interaction between a coil and a permanent magnet. The balance generates a magnetic force to counteract the weight of the object being measured, with the current through the coil adjusted to maintain equilibrium. Electromagnetic compensation blocks are known for their high precision, making them ideal for analytical and semi-micro balances.

- Load Cell: Load cells are strain gauge-based sensors that measure the deformation of a solid body under a load. When weight is applied, the strain gauges detect the deformation and provide weight measurements. They are versatile and used in a wide range of applications, including industrial scales and some laboratory balances.

2. Precision and Accuracy:

- Electromagnetic Compensation Block: Offers extremely high precision and accuracy for sensitive measurements, making it ideal for analytical weighing.

- Load Cell: Provides good precision and accuracy, suitable for a broad range of applications.

3. Application:

- Consider your specific use case. Are you performing analytical weighing, quality control, or general lab work? Choose a balance that matches your requirements.

4. Durability:

- Electromagnetic Compensation Block: Delicate and may require more careful handling to avoid damage to the coil and magnet.

- Load Cell: Typically more robust and less prone to damage, making them suitable for rugged environments.

5. Cost:

- Electromagnetic Compensation Block: Generally more expensive due to high precision and specialized use.

- Load Cell: Offers a cost-effective solution for a variety of applications.

6. Capacity and Readability:

- Ensure the balance’s capacity and readability (the smallest weight it can measure) meet your specific needs. Balances come in a wide range of capacities and readabilities.

7. Calibration and Maintenance:

- Consider the ease of calibration. Some balances offer internal calibration, making the process more convenient, while others require external calibration. Also, factor in the maintenance requirements, as some balances may require more frequent calibration, affecting the cost of ownership.

8. Maximum Weight Range:

- Check the maximum weight range of the balance. Some balances are designed for micro-scale measurements, while others can handle larger quantities. Ensure it aligns with your intended use.

9. Connectivity and Features:

- Determine if you need additional features like data connectivity (USB, Bluetooth), touchscreen interfaces, or built-in applications such as density determination or pipette calibration.

10. Compliance and Standards:

- If your work requires adherence to specific industry standards or regulations, ensure that the selected balance meets those requirements.

11. Interlab’s Baxtran Balance Range:

- At Interlab, we proudly offer a range of high-quality Baxtran balances manufactured in Spain. Baxtran balances are renowned for their exceptional quality and performance, making them a trusted choice in the balance and scale industry. Their impact spans from weighbridges to analytical lab balances, serving a diverse range of applications.

Choosing the right lab balance is crucial for obtaining accurate and reliable measurements in your laboratory or work environment. By considering these factors and carefully assessing your specific needs, you can make an informed decision that ensures the balance you select is the perfect fit for your applications.