To choose the correct membrane filter for your laboratory and application is an important and precise task. You need to be sure that the membrane filter you choose is suited to a few different conditions, which we will discuss in this article. Choosing the correct membrane filters, used in microbiological and air pollution applications, will be explained in this article.

To order your Membrane Filters today, take a look at our range of filters here.

You can also order via email: sales@interlab.co.nz or fax: 04 939 6170 or just give us a FREE call 0508 331 331

1. How do I select the correct Membrane Filter type for my laboratory?

Micro-filtration is one kind of physical filtration process where a contaminated fluid is passed through a special pore size membrane to separate micro-organisms and suspended particles from process liquid or gas. the typical pore size used for micro-filtration ranges from 0.1 to 10um. Interlab offers full membrane filters for various solvents or liquids or gas. Most membranes can be sterilized if needed.

The Membrane filter you select will depend on a number of factors. Interlab has membrane filters for all applications available, so you need to look at the following before deciding:

- Consider which liquid (solvent or aqueous) or air/gas will be filtered

- Check the chemical resistance and compatibility

- Check the maximum pore size required to achieve the results

- Check the membrane specifications for any unusual process conditions (temperature, pressure)

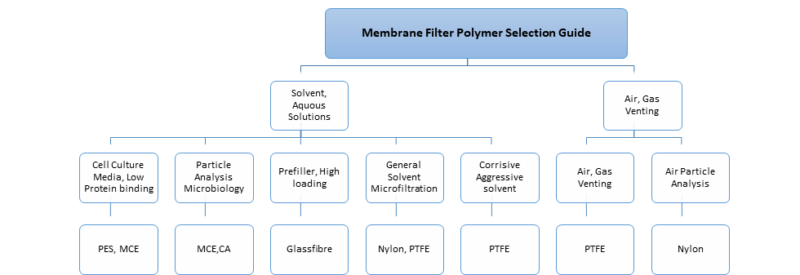

This Membrane Filter Polymer Selection Guide will give you a better understanding of the correct choice for the application you intend the membrane filter for.

Membrane filter applications include:

Membrane filter applications include:

- General clean and filtration

- Sample Preparation

- Environmental Monitoring and Analysis

- Filtration of Aqueous and Organic Solutions

- Fluid Monitoring

- Pharmaceutical Products Analysis

- Chromatography and Mass Spec Sample Preparation

- Venting and Gas Filtration

Interlab offers a range of membrane filters and other filters for various applications. If you are unsure of the type that is best for your application contact us to discuss further and we will be happy to assist. sales@interlab.co.nz or fax: 04 939 6170 or just give us a FREE call 0508 331 331

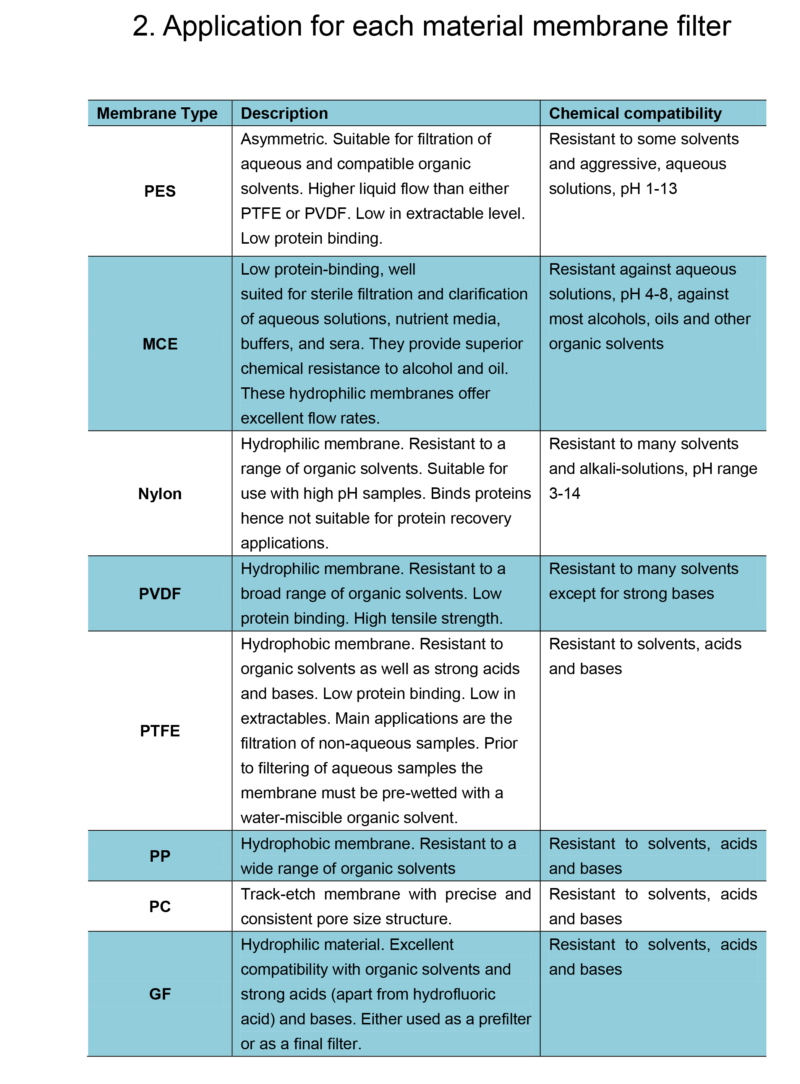

3. Below is the description of the application and chemical compatibility of each type of membrane filter:

- GF Membrane Filters: Made from hydrophilic material. Excellent compatibility with organic solvents and strong acids (apart from hydrofluoric acid) and bases. Either used as a prefilter or as a final filter. Resistant to solvents, acids and bases.

- MCE Membrane Filters: This is low protein-binding, well suited for sterile filtration and clarification of aqueous solutions, nutrient media, buffers, and sera. They provide superior chemical resistance to alcohol and oil. These hydrophilic membranes offer excellent flow rates. Resistant against aqueous solutions, pH 4-8, against most alcohols, oils and other organic solvents.

- Nylon Membrane Filters: This is a hydrophilic membrane. Resistant to a range of organic solvents. Suitable for use with high pH samples. Binds proteins hence not suitable for protein recovery applications. Resistant to many solvents and alkali-solutions, pH range 3-14

- PC Membrane Filters: Track-etch membrane with precise and consistent pore size structure. Resistant to solvents, acids and bases.

- PES Membrane Filters: Asymmetric. Suitable for filtration of aqueous and compatible organic solvents. Higher liquid flow than either PTFE or PVDF. Low in extractable level. Low protein binding. Resistant to some solvents and aggressive, aqueous solutions, pH 1-13

- PP Membrane Filters: Hydrophobic membrane. Resistant to a wide range of organic solvents, acids and bases.

- PTFE Membrane Filters: Hydrophobic membrane. Resistant to organic solvents as well as strong acids and bases. Low protein binding. Low in extractables. Main applications are the filtration of non-aqueous samples. Prior to filtering of aqueous samples the membrane must be pre-wetted with a water-miscible organic solvent. Resistant to solvents, acids and bases.

- PVDF Membrane Filters: Hydrophilic membrane. Resistant to a broad range of organic solvents. Low protein binding. High tensile strength. Resistant to many solvents except for strong bases.

Information supplied courtesy of Membrane Solutions.