Interlab supplies a wide range of ultrasonic cleaners, but we often get asked the same question: How does this even work? If you’ve ever dropped glassware into an ultrasonic bath and watched as weeks of grime melt away in minutes, it can seem like something magical is going on.

Well, there’s no magic here, just cavitation, and it’s one of the most powerful (and fascinating) cleaning mechanisms you’ll ever encounter.

What is cavitation?

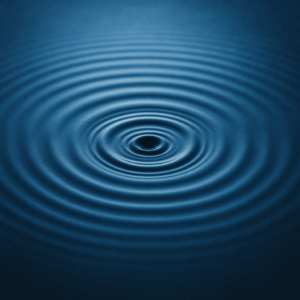

Cavitation is a physical phenomenon that happens when sound waves move through liquid. Ultrasonic cleaners generate high-frequency sound waves, usually between 35 and 45 kHz, through a transducer attached to a metal tank filled with water or cleaning solution.

These sound waves compress and expand the liquid at rapid intervals, creating microscopic vacuum bubbles. When these bubbles collapse, they release an enormous burst of energy, on a tiny scale. It’s this rapid collapse, or implosion, that gives cavitation its cleaning power.

You’re essentially unleashing thousands of tiny scrubbing bubbles per second, all hitting the surface of your item from every angle.

So how does this clean?

Each collapsing bubble creates a micro-jet of energy that knocks contaminants loose from the surface of the item being cleaned. Because the process works at a microscopic level, ultrasonic cleaning can reach places no brush or cloth ever could, like fine threads, narrow tubes, grooves, crevices, and internal surfaces.

It’s not just about removing visible dirt either. Cavitation can dislodge:

- Residual powders

- Oils and greases

- Metal filings

- Biofilms

- Oxidation and flux

- Even blood, proteins, and tissue residue from surgical tools

And because it’s all happening in a uniform bath, it cleans thoroughly and consistently without scratching, bending, or wearing down the object.

What can you clean with it?

Ultrasonic cleaners are used across dozens of industries, including:

- Laboratories – for glassware, pipette tips, test tube racks, and stainless steel tools

- Dental and medical – for surgical instruments, forceps, implant tools

- Jewellery and watchmaking – for fine chains, bezels, stones, and mechanical parts

- Industrial workshops – for degreasing bearings, carburettors, precision parts

- Electronics – for cleaning PCBs, solder flux, and dust from tiny components

In the lab, they’re especially useful when you need reliable, residue-free results without harsh mechanical scrubbing.

Cavitation might be invisible… but the results speak for themselves.

The next time you drop a beaker, watch part, or instrument into an ultrasonic cleaner, take a moment to think about what’s happening. Thousands of tiny implosions per second, cleaning in places you can’t even see, all with minimal effort and no damage.

That’s cavitation, and it’s kind of magic.

If you’re looking to equip your lab, clinic, or workshop with a reliable ultrasonic cleaner, our team can help you choose the right size and features for your needs.

Browse our range of ultrasonic cleaners or get in touch with us:

sales@interlab.co.nz

Call +64 4 972 2330.